Wafer AOI

FAB graphic wafer detection equipment Zhuhai Chengfeng Electronic Technology Co., Ltd. was established in 2015 and has complete optical and software hardware system design integration and production capabilities. Committed to becoming a leading provider of semiconductor testing equipment solutions in the industry. Focusing on FAB graphic wafer inspection, we customize mainstream AOI products suitable for both FAB front-end and back-end processes for our customers. The Chengfeng software and hardware R&D team adheres to full stack independent research and development, deeply cultivates the integration of traditional algorithms and AI algorithms in machine vision technology. After years of industry accumulation, they have achieved multiple core technology achievements in light source paths and detection algorithms that are comparable to industry-leading technologies, and have received orders and batch repeat orders from multiple well-known customers. Optical imaging technology: light and dark field composite optical path, transparent wafer imaging, fluorescence optical path imaging, infrared penetration imaging. Wafer Type: Bare/Taiko/Shin Application: ADI/AEI/Post CMP/Advanced Packaging/Cutting Path/OQC Applicable fields: FAB front-end process control and back-end process testing 5 in 1 multifunctional: Crystal plane detection, back detection, edge detection, wafer warping measurement, wafer thickness measurement Equipment parameters: Camera: Chengfeng custom high-speed high-resolution color camera Light source: Chengfeng self-developed Wafer specialized light and dark field composite light source Pixel resolution: 170 nm@20X Magnification: 2X/5X/10X/20X, 50X/100X Detection capability: 1Pixel (AI) Detection algorithm: AI/ML Detectable types: poor graphics, cracks, scratches, needle marks, dents, dirt, foreign objects, chipping, etc Missing detection rate: ≤ 0.001%, low kill rate

Classification

CFW820 FAB front section defect detection

Wafer AOI

Chengfeng Technology focuses on the research and application of nanoscale patterned wafer detection equipment. The founding core members of the company have been deeply involved in the fields of optical design and visual algorithms for over 20 years. Based on our focus and professional genes in the field of semiconductor visual defect detection, our company has a deep accumulation of optical path design and scene detection algorithms. We have specifically designed a series of scene based dual light path dual camera/light and dark field composite light path/laser composite light path solutions for specific sub fields of wafer manufacturing, combined with accumulated scene based AI detection algorithms, benchmarking against global leading technologies, Currently, it has been implemented in various fields such as silicon optical wafers, optical communication lenses, synthetic semiconductors, and digital wafers.

Show Detail

Technical parameters:

1. Based on Die to Die detection algorithm 2. Support for bright field lighting path 3. Support IntelligentLight for composite light paths in both light and dark fields 4. Supports infrared perspective imaging (RedBoy) 5. Supports AutoFocus 6. Support defect re judgment/analysis tools 7. Optional single/dual channel working mode 8. Supports full/semi-automatic working modes Product features: CFW820: AOI, quick screening of major defectsCFW920 FAB front stage process control

Wafer AOI

Chengfeng Technology focuses on the research and application of nanoscale patterned wafer detection equipment. The founding core members of the company have been deeply involved in the fields of optical design and visual algorithms for over 20 years. Based on our focus and professional genes in the field of semiconductor visual defect detection, our company has a deep accumulation of optical path design and scene detection algorithms. We have specifically designed a series of scene based dual light path dual camera/light and dark field composite light path/laser composite light path solutions for specific sub fields of wafer manufacturing, combined with accumulated scene based AI detection algorithms, benchmarking against global leading technologies, Currently, it has been implemented in various fields such as silicon optical wafers, optical communication lenses, synthetic semiconductors, and digital wafers.

Show Detail

Equipment parameters:

1. Camera: Chengfeng custom high-speed high-resolution color camera 2. Light source: Chengfeng self-developed Wafer specialized light and dark field composite light source 3. Pixel resolution: 170 nm@20x 4. Magnification: 2X/5X/10X/20X, 50X/100X 5. Detection capability: 1Pixel (AI) 6. Detection algorithm: AI/ML 7. Detectable types: poor graphics, cracks, scratches, needle marks, dents, dirt, foreign objects, chipping, etc 8. Missing detection rate: ≤ 0.001%, low kill rateProduct features:

1. Based on Die to Die detection algorithm 2. Supports AutoFocus 3. Supports infrared perspective imaging (RedBoy) 4. Support defect re judgment/analysis tools 5. Equipped with independent image sensors, it can support large-sized Dies 6. supports dual channel mode, and front/back detection can be performed simultaneously. The two channels can adopt different magnification and optical path designs 7. The software can distinguish different defects and label them, and summarize the number of defects. If the limit value is exceeded, an alarm will be triggered 8. software can set the threshold parameters for Defects according to different regions, and specific regions can also be set as Skip regions 9. Different regions can be configured to use different magnification combinations for detectionCFW380 FAB rear section defect detection

Wafer AOI

The CFW380 multifunctional Wafer detection device launched by Chengfeng Technology is suitable for Wafer surface defect detection before and after slicing (supporting cutting path detection). The founding core members of the company have been deeply involved in the fields of optical design and visual algorithms for over 20 years. Based on our focus and professional genes in the field of semiconductor visual defect detection, our company has a deep accumulation of optical path design and scene detection algorithms. We have specifically designed a series of scene based dual optical path dual camera/light and dark field composite optical path/laser composite optical path solutions for specific sub fields of wafer manufacturing, combined with accumulated scene based AI detection algorithms, benchmarking against global leading technologies. Currently, we have been implemented in various fields such as GPP wafers/silicon optical wafers/optical communication lenses/composite semiconductors/digital wafers.

Show Detail

Applicable fields:

1) FAB quality final inspection 2) Wafer scratch detection 3) Detection after wafer expansionEquipment parameters:

1. Camera: Chengfeng custom high-speed high-resolution color camera 2. Light source: Chengfeng self-developed Wafer specialized light and dark field composite light source 3. Pixel resolution: 2.4 μ M @ 2X 4. Magnification ratio: 1X/2X/5X 5. Defect detection accuracy: ≥ 1 micrometer 6. Missing detection rate: ≤ 0.01% (serious defects can achieve 0 missed detections) 7. Comprehensive efficiency: ≤ 4 minutes (data with a resolution of 8 inches @ 2 microns) 8. Detectable types: poor graphics, cracks, scratches, needle marks, dents, dirt, foreign objects, chipping, etcProduct features:

1. Back detection: Supports wafer back detection (optional) 2. OCR: Supports OCR (optional) 3. Reading method: Supports RFID reading (optional) 4. Access port: Supports SECS/GEM protocol 5. Supported size: Supports 4/6/8/12 inch wafers 6. Loadport: Supports 2 Loadports 7. Device output: MAP image/inkjet marking (optional) 8. Cutting path: supports cutting path detection 9. Re judgment mode: supports both automatic and manual re judgment modes

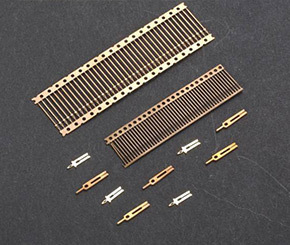

Passive component inspecting equipment

KLA的缺陷检测与复检视系统支持芯片和晶圆制造环境中各种不同的良率应用,包括进厂工艺设备认证、晶圆认证、研究和开发以及设备、工艺和生产线监控。图案化和非图案化的晶圆缺陷检测与复检系统可以捕获并识别晶圆前后表面以及边缘上的颗粒和图案缺陷,并对其进行分类。该信息将帮助工程师发现、解决并监控关键的良率偏移,从而加快良率提升并达到更高的产品良率。

Passive component inspecting equipment

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Passive component inspecting equipment

KLA的缺陷检测与复检视系统支持芯片和晶圆制造环境中各种不同的良率应用,包括进厂工艺设备认证、晶圆认证、研究和开发以及设备、工艺和生产线监控。图案化和非图案化的晶圆缺陷检测与复检系统可以捕获并识别晶圆前后表面以及边缘上的颗粒和图案缺陷,并对其进行分类。该信息将帮助工程师发现、解决并监控关键的良率偏移,从而加快良率提升并达到更高的产品良率。

Passive component inspecting equipment

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Company address: Building 4, Zhongdian High tech Industrial Park, Keji 7th Road, Tangjiawan Town, High tech Zone, Zhuhai City, Guangdong Province

Company address: Wanlong Building, No. 29 Xinfa Road, Suzhou Industrial Park, Suzhou City, Jiangsu Province

Company address:Comprehensive Protection Building at the Intersection of Dongfang Avenue and Dayu Road in Xinzhan District, Hefei City, Anhui Province

Company address: Building 1, Investment Promotion High tech Network Valley, Donghu High tech Zone, Wuhan City, Hubei Province

Stay Connected

Copyright © 2022 Zhuhai Chengfeng Electronic Technology Co., Ltd.