Passive Component Inspecting Equipment

The hexahedral appearance detection and sorting equipment can eliminate the wrong detection and missing detection caused by fatigue in eye detection by self-developed algorithm. The system parameter setting is simple and the detection specifications are unified. It can quickly and accurately identify all kinds of small defects on the surface of all kinds of fine products. Using ultra-high resolution cameras imported from Germany and self-developed high-precision algorithms, according to customer needs, it can realize fine material detection of various shapes, accurately detect a variety of surface defects of products, with accuracy up to pixel level, and at the same time, it can achieve positive and negative recognition, classification and other functions.

Applicable fields

Classification

Mouth shaped magnetic core appearance inspection sorting machine CF-660

Passive Component Inspecting Equipment

Detection efficiency: 1010: 500~550pcs/min 1212: 400~500pcs/min 1515: 250-350pcs/min CCD accuracy: 0.005mm/pixel Camera configuration: 6 cameras

Show Detail

Advantages and characteristics

Chengfeng is the first domestic AOI supplier to truly help customers solve the difficulties of inner ring testing, We have taken the lead in introducing the equipment to a large domestic magnetic ring head factory, focusing on issues such as missed detection rate and direct pass rate Fully leading in indicators, truly achieving AOI's missed detection rate in this field At a level of 1/10000, it meets the testing needs of high-end customers. Inspection items: size, chipping, edge chipping, defects, stains, pits, indentations, cracks, deformations, and other visual defectsApplicable field: mouth shaped magnetic core

Circular/irregular components AOI CF710

Passive Component Inspecting Equipment

Comprehensive detection efficiency: 40-50pcs/min Detection resolution: 5-10 microns Detectable defect types: cracks/dark cracks/chipping/peeling/deformation/dirt and other appearance defects Maximum workstations: 11 (each capable of 360 degree rotation and flying) Number of cameras: 6-11 (configured as needed) Camera resolution: 1.6 million/5 million/12 million (configured as needed) Detection method: Each workstation can independently rotate 360 degrees and fly to detect all areas Supported component sizes: Minimum: 3mm * 3mm Maximum: 80mm * 80mm

Show Detail

Advantages and characteristics

Automatic feeding mode: Shaking the vibration disk or robot module to the detection brick tower waiting area (configured according to requirements) Automatic cutting method: NG/OK products are sorted through belt cutting, and OK products support swing plates (customized according to needs)Magnetic Ring Appearance Inspection Sorter CF-650

Passive Component Inspecting Equipment

10mm outer diameter magnetic ring: 450-500pcs/min CCD Precision: 0.004mm/pixel 6 cameras: Front: 1 camera Back: 1 camera Outer side: 4 cameras Inner side: 4 cameras (customer selectable)

Show Detail

Applicable field: magnetic ring

Advantages and characteristics

Chengfeng is the first domestic AOI supplier to truly help customers solve the difficulties of inner ring testing, We have taken the lead in introducing the equipment to a large domestic magnetic ring head factory, focusing on issues such as missed detection rate and direct pass rate Fully leading in indicators, truly achieving AOI's missed detection rate in this field At a level of 1/10000, it meets the testing needs of high-end customers. Inspection items: size, chipping, edge chipping, defects, stains, pits, indentations, cracks, deformations, and other visual defectsHigh speed appearance inspection sorter CF-690

Passive Component Inspecting Equipment

Equipment specification: 1.1*1*1.93m Product power: 3600~5500W Inspection width: 0.5~5mm Detection accuracy: 0.002mm Operation speed: 2000~8000pcs/min

Show Detail

Advantages and characteristics

Based on defect detection experience in chip field, self-developed software algorithm is specially tailored for patch resistance /MLCC detection, leading in the industry. It can detect defects such as rupture/missing/offset/bad electrode/stain/unclear character code with low leakage rate and high pass-through rate. Traditional vision +AI detection has a wide coverage of defects. Software and visual algorithms full stack self - developed.Application field: Chip resistance/MLCC

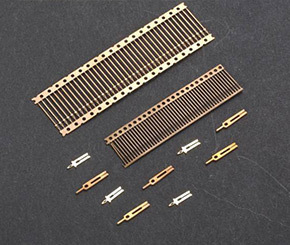

GPP wafer appearance inspection sorter CF-640

Passive Component Inspecting Equipment

Equipment specification: 1.1*1*1.93m Product power: 3600~5500W Inspection width: 1~6mm Detection accuracy: 0.002mm Operation speed: 800~3000pcs/min

Show Detail

Advantages and characteristics

Relying on the flaw detection experience in the chip field, the self-developed software algorithm is specially tailored for GPP wafer detection. It is the only equipment in the industry that can detect 4mm GPP wafers. Detect defects such as cavity/edge collapse/corner/multilateral, with low leakage rate. 4 cameras in the standard version/6 cameras in the high configuration version can cover most defects. Vibrating disc/camera/industrial personal computer are all top brands of Japan/Germany/Taiwan.Application field: wafer

Chip diode appearance inspection sorter CF-630

Passive Component Inspecting Equipment

Equipment specification: 1.1*1*1.93m Product power: 3600~5500W Inspection width: 1~20mm Detection accuracy: 0.006mm/pixel Operation speed: 400~1200pcs/min

Show Detail

Advantages and characteristics

Relying on the flaw detection experience in the chip field, the self-developed software algorithm is specially tailored for chip diode detection, leading the industry. It can detect such defects as edge chipping/corner chipping/cracks/size deviation/plating area defects, with low leakage rate, high pass through rate and high detection rate of crack AI detection algorithm. The standard version has 6 cameras, which can cover most defects. Vibrating disc/camera/industrial personal computer are all top brands of Japan/Germany/Taiwan.Application field: Chip diode

Molding Choke appearance inspection sorter CF-620

Passive Component Inspecting Equipment

Equipment specification: 1.1*1*1.93m Product power: 3600~5500W Inspection width: 0.5-15mm Detection accuracy: 0.002mm Operation speed: 500~1500pcs/min

Show Detail

Advantages and characteristics

Relying on the flaw detection experience in the chip field, the self-developed software algorithm is specially tailored for magnetic core detection, leading the industry. It can detect such defects as edge collapse/corner collapse/crack/dark crack, low leak rate, high pass rate, and high detection rate of crack A detection algorithm. Six cameras in the standard version/eight cameras in the high configuration version can cover most defects. Vibrating disc/camera/industrial personal computer are all top brands of Japan/Germany/Taiwan.Application field: Molding Choke

Magnetic core appearance inspection sorter CF-610

Passive Component Inspecting Equipment

Equipment specification: 1.1*1*1.93m Product power: 3600~5500W Inspection width: 0.5-15mm Detection accuracy: 0.002mm Operation speed: 500~1500pcs/min

Show Detail

Advantages and characteristics

Relying on the flaw detection experience in the chip field, the self-developed software algorithm is specially tailored for magnetic core detection, leading the industry. It can detect such defects as edge collapse/corner collapse/crack/dark crack, low leak rate, high pass rate, and high detection rate of crack A detection algorithm. Six cameras in the standard version/eight cameras in the high configuration version can cover most defects. Vibrating disc/camera/industrial personal computer are all top brands of Japan/Germany/Taiwan.Application field: Magnetic core

Passive component inspecting equipment

KLA的缺陷检测与复检视系统支持芯片和晶圆制造环境中各种不同的良率应用,包括进厂工艺设备认证、晶圆认证、研究和开发以及设备、工艺和生产线监控。图案化和非图案化的晶圆缺陷检测与复检系统可以捕获并识别晶圆前后表面以及边缘上的颗粒和图案缺陷,并对其进行分类。该信息将帮助工程师发现、解决并监控关键的良率偏移,从而加快良率提升并达到更高的产品良率。

Passive component inspecting equipment

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Passive component inspecting equipment

KLA的缺陷检测与复检视系统支持芯片和晶圆制造环境中各种不同的良率应用,包括进厂工艺设备认证、晶圆认证、研究和开发以及设备、工艺和生产线监控。图案化和非图案化的晶圆缺陷检测与复检系统可以捕获并识别晶圆前后表面以及边缘上的颗粒和图案缺陷,并对其进行分类。该信息将帮助工程师发现、解决并监控关键的良率偏移,从而加快良率提升并达到更高的产品良率。

Passive component inspecting equipment

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Company address: Building 4, Zhongdian High tech Industrial Park, Keji 7th Road, Tangjiawan Town, High tech Zone, Zhuhai City, Guangdong Province

Company address: Wanlong Building, No. 29 Xinfa Road, Suzhou Industrial Park, Suzhou City, Jiangsu Province

Company address:Comprehensive Protection Building at the Intersection of Dongfang Avenue and Dayu Road in Xinzhan District, Hefei City, Anhui Province

Company address: Building 1, Investment Promotion High tech Network Valley, Donghu High tech Zone, Wuhan City, Hubei Province

Stay Connected

Copyright © 2022 Zhuhai Chengfeng Electronic Technology Co., Ltd.